Advanced Tubular & Surface Inspection

Through our extensive suite of applications, we can test a wide range of ferrous and non-ferrous materials for flaws including corrosion, cracking, and other damage mechanisms.

Advanced Inspection Technology

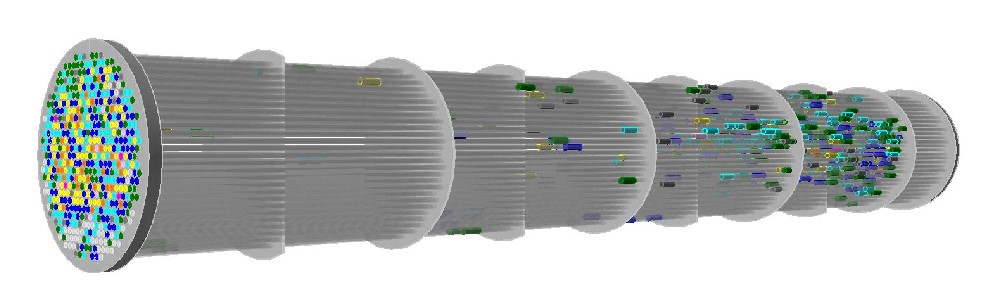

AIT is among the industry leaders using revolutionary technology as well as highly trained personnel (over 85 years of combined experience) to provide Eddy Current, Eddy Current Array, Remote Field, Near Field, IRIS, Tube End Gauging, Remote Visual Inspections, Surface Eddy Current, and Array Surface Eddy Current. With the addition of the Eddyfi Ectane equipment, AIT has the ability to provide the top tubular and surface inspections available and give visual images, when applicable, with Olympus IPLEX video scopes. TubePro software is used for advanced reporting and automated 3D images.

Eddy Current Inspection

- Best inspection for non-ferromagnetic tubing

- High rate of inspection (Probe Driver increases productivity)

- Sensitive to gradual wall loss, corrosion, pitting, erosion, baffle wear, transverse cracking, and other discontinuities

Remote Field Testing (RFT)

- Inspection of ferromagnetic tubing

- Sensitive to general corrosion, pitting, baffle wear, cracking

- Equal sensitivity to the detection of ID and OD defects

Remote Visual Inspection

- High-quality video scopes

- Used to verify ID indications and cleanliness of the tubes inspected with all testing techniques

Eddy Current Array (ECA)

- The Eddy Current Array + Bobbin probe technology is the solution to perform a high-resolution inspection at the bobbin speed in a single pass

- High sensitivity to pitting and circumferential cracking (ID and OD circ. Cracks detected down to 20% depth)

- Reliable characterization of flaws with C-scan Imaging and Terrain Plotting

- Improved detection of all damage mechanisms at the roll area / tubesheet and under support plates

Near Field Testing (NFT)

- This technique is generally used for inspecting externally finned ferrous tubing

- Limited only for ID indications such as general corrosion and pitting

IRIS (Internal Rotational Inspection System)

- Versatile inspection technique suitable for ferrous and non-ferrous materials

- Very accurate for thickness measurements

- This technique is often used to verify RFT and NFT to get additional information on the geometry of defects

- Can detect and size defects under tube sheets and baffles

Surface Eddy Current Array

- Can be made rigid or flexible to match the geometry of the inspection piece

- Plots all indications into a 2-D C-Scan / 3-D Terrain Plot which improves flaw detection and sizing

- Covers more surface area with one pass of the probe

- Can be used in lieu of Liquid Penetrant and Magnetic Particle testing

Tube End Gauging

- Accurately measure tube ID’s

- Three-point ball contact to obtain a precise measurement reading provided by the dial plate

- This technique is typically used to complement any inspection where tube end thinning has been detected

Interested in learning more?

Our existing team members have worked together for 20+ years and have extensive combined experience in Eddy Current, Phased Array, API Inspections, Advanced Radiography, and Traditional NDE Methods. Our team has the highest level of training and certification using that expertise to find new solutions to your Asset Integrity issues.

Let's discuss your next project.

Our team has worked in Oil and Gas (upstream, midstream, and downstream), mining, power generation, and many others. Our team values the long-term relationships it makes with our customers as evidenced by our strong repeat business requests.